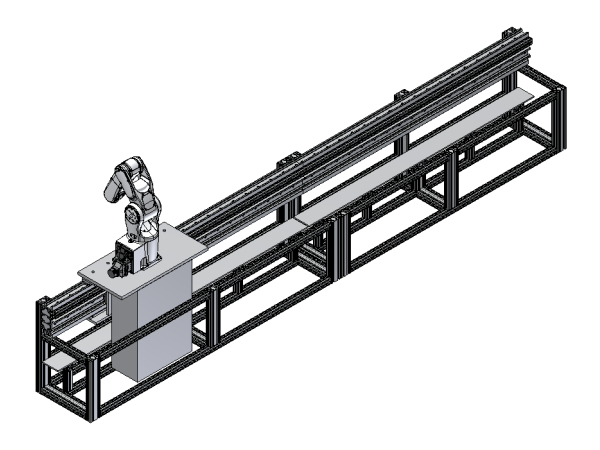

Move robots It can be long stroke transferred a robot itself by easily connected mechanism

In recent years, automation using robots has been promoted in various fields including the industrial world in order to labor shortages, efficiency and reduce heavy labor.

However, a robot is expensive, and even if it introduced them, there are many issues to be solved.

For example, such as the solution to waiting time for the robots when there is a difference in completion time for each process, or in case of necessary to increase or decrease equipment due to process changes. Otherwise, difficult to change layout after installed robot, etc.

The robot transfer system developed by us can take care of multiple processes with a single robot, therefore, possible to reduce costs and standby time.

In addition, each unit is modularized, making it easy to increase or decrease the number of units to suit the process, or layout change

Click here for product features(jump to the bottom of page) Click here for product introduction video(jump to the bottom of page)

Click here to download the catalog Click here for inquiries

RHLS80160V

(Wireless power feed type)

Max workpiece weight:4kg

Max speed:1m/s

Recommended for short waiting times

※Without a robot, control devices, and program

RHLSI65H

(Battery quick charge type)

Max workpiece weight:7kg

Max speed:1m/s

Recommended for long waiting times

※Without a robot, control devices, and program

【Features】

■ Guide mechanism, drive units, wireless power feeder, and robot control devices are installed in a carriage※1

■ Each unit is modularized at 2m. Therefore, making it easy to increase or decrease the number of units, long stroke transfer and layout change also

■ Using OZAK original Linear roller Sliders suitable for long stroke and rail to rail transfer. And a rack and pinion are used for drive unit.

■ Power is supplied by a non-contact method that does not depend on cable length. Lineup is two types, wireless power feed type and battery quick charge type

■ Wireless power feed type can be equipped with a robot for maximum weight capacity is 4 kg, and battery quick charge type is 7 kg※2

■ Cranes or other equipment are unnecessary when increase or decrease of units or layout change because trestle is structured lightweight aluminum frames and can be moved easily

※1 Robot transfer system does not include a robot, control devices, and program

※2 It may need to change specifications depending on a robot to be mounted.For more information, please contact us from the following

Click here for inquiries Click here for dimensions and CAD data(jump to the above of page)

Click here to download the catalog

【Product Introduction Video】

In this video, the mounted robot itself is transferred (Rail Guided Vehicle method) and driven autonomously by a camera and AI.

Click here to download the catalog Click here for dimensions and CAD data(jump to the above of page)

【Related product】